LLDPE vs LDPE Plastic: What’s the Difference?

The first step to identifying and moving forward with the best polyethylene resin for your project needs? Understanding which PCR resin compound is right for your application: linear low density polyethylene film (LLDPE film) or low density polyethylene film (LDPE resin).

Durability vs Versatility: Choosing Between LLDPE and LDPE

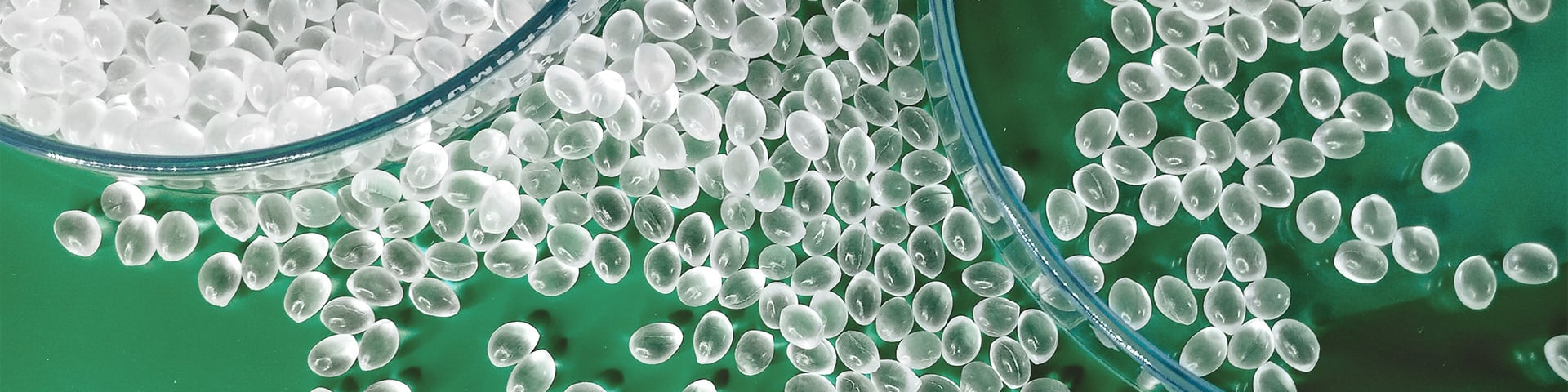

LLDPE and LDPE pellets may look similar on the surface, but their structure, performance and usage applications couldn’t be more different. Let’s start on a molecular level.

As its name suggests, linear low density polyethylene (LLDPE) features a linear polymer chain with short, uniform branches that boost durability and puncture resistance. Available in both multi-purpose and food safe resin grades, our LLDPE film introduces a whole new level of strength and purity to post consumer recycled solutions.

While this stronger, more resilient polyethylene compound might be more durable than low density polyethylene (LDPE), it lacks the versatility and flexibility LDPE polythene brings to the table. LDPE resin’s highly branched molecular structure results in a softer, more dynamic material.

Every batch of LLDPE film and LDPE resin is backed by our rigorous quality controls, made from high-grade post consumer recycled resin and tailored to meet each clients’ real world needs. Our custom polymer synthesis service provides smarter plastic solutions for every application from lightweight retail packaging to industrial-grade stretch film. To put it simply, Natura PCR delivers recycled polyethylene solutions that meet performance demands without compromise.

Linear Low Density Polyethylene Film: Two Grades, One Purpose

From durable food safe resins to high-strength industrial wrap, linear low density polyethylene film (LLDPE film) delivers the strength and consistency today’s manufacturers demand — all while using 100% recycled materials. Our two specialized grades of LLDPE start with the same foundation: transforming high-quality materials into clean, uniform and durable plastic resin pellets.

Headline PCR For Every Client Need Lorem

Short statement providing an overview of the different areas of disconnect in the closed loop economy - scalability, quality, supply chain, and highlight opportunities

Headline PCR For Every Client Need Lorem

Short statement providing an overview of the different areas of disconnect in the closed loop economy - scalability, quality, supply chain, and highlight opportunities

3 Blocks Module

Consectetur adipisicing elit, sed do eiusmod tempor ut labore et dolore magna aliqua.

H3 LLDPE Industrial Grade ipsum dolor sit amet, consectetur

Lorem ipsum partnership with WM provides us with an endless supply of grade A post-consumer plastic waste lorem.

H3 LLDPE Industrial Grade ipsum dolor sit amet, consectetur

Lorem ipsum partnership with WM provides us with an endless supply of grade A post-consumer plastic waste lorem.

H3 LLDPE Industrial Grade ipsum dolor sit amet, consectetur

Lorem ipsum partnership with WM provides us with an endless supply of grade A post-consumer plastic waste lorem.

Icons Headline

Consectetur adipisicing elit, sed do eiusmod tempor ut labore et dolore magna aliqua.

Header for the Icon Element that Would Go Here

Sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Header for the Icon Element that Would Go Here

Quis ipsum suspendisse ultrices gravida. Egola spacorum vici sunt

Header for the Icon Element that Would Go Here

Risus commodo viverra maecenas accumsan lacus vel facilisis.

Header for the Icon Element that Would Go Here

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

H3 Headline lorem ipsum dolor sit amet, adipisicing elit

Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum. Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium doloremque laudantium, totam rem aperiam, eaque ipsa quae ab illo inventore veritatis et quasi architecto beatae vitae dicta sunt explicabo.

H3 Headline lorem ipsum dolor sit amet, adipisicing elit

Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum. Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium doloremque laudantium, totam rem aperiam, eaque ipsa quae ab illo inventore veritatis et quasi architecto beatae vitae dicta sunt explicabo.

Meet Our Team

Consectetur adipisicing elit, sed do eiusmod tempor ut labore et dolore magna aliqua.

Dave Grice

Title/Position

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

- Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

- Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur.

Dave Grice

Title/Position

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

- Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

- Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur.

Dave Grice

Title/Position

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

- Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

- Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur.

By the Numbers

Consectetur adipisicing elit, sed do eiusmod tempor ut labore et dolore magna aliqua.

Tabbed Content

Consectetur adipisicing elit, sed do eiusmod tempor ut labore et dolore magna aliqua.

Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore.

CALL TO ACTION

Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore.

CALL TO ACTION

Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore.

CALL TO ACTION

Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore.

CALL TO ACTION

Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore.

CALL TO ACTION

Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore.

CALL TO ACTION

Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore.

CALL TO ACTION

Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore.

CALL TO ACTION

Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore.

CALL TO ACTION

Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore.

CALL TO ACTION

Our People Are Our Purpose

Consectetur adipisicing elit, sed do eiusmod tempor ut labore et dolore magna aliqua.

Andrew James

Field Engineer, 31

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequa

Kathleen S. Goodwin

VP of Technology, 58

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequa

Kevin L. Nguyen

Software Engineer, 34

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequa

Maura Jenkins

HR Manager, 37

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequa

Two Grades, One Purpose

From durable food safe resins for food and beverage packaging to high-strength industrial wrap, linear low density polyethylene film (LLDPE film) delivers the strength and consistency today’s manufacturers demand — all while using 100% recycled pcr material. Our two specialized grades of LLDPE start with the same foundation: transforming high-quality materials into clean, uniform and durable plastic resin pellets.

What’s the difference between LLDPE food safe resin and multi-purpose LLDPE film?

While both are made from high-quality PCR recycled materials, the main difference between multi-purpose LLDPE film and LLDPE food safe resin lies in how they’re sourced processed, and ultimately used.

Multi-purpose FDA compliant plastic film is engineered for general industrial and commercial packaging applications, while LLDPE food safe resin is sourced exclusively from FDA-vetted, food-contact-approved distribution centers and processed on dedicated food safe production lines.

What is LLDPE food safe resin?

LLDPE food safe resin is a high-performance, FDA-compliant plastic specifically designed for food grade packaging applications. Made from post-commercial shrink wrap and film collected only from vetted food packaging suppliers, this lldpe plastic aligns with strict food packaging materials standards.

Is LLDPE food safe resin FDA-compliant?

Yes. Natura PCR’s LLDPE food safe resin is a fully FDA compliant plastic and meets the requirements for direct food contact (less than 3% contamination). All feedstock is sourced from approved food distribution centers, where materials are certified safe for reuse. Each bale is individually inspected and graded. If contamination exceeds 3%, the bale is repurposed to create multi-purpose LLDPE film. LLDPE food grade bags for food packaging are ideal for sustainable, high-quality polymer compounding in direct contact with goods like small food packaging, sandwich bags, produce film and shrink wrap for food packaging containers.

What are the best uses for LLDPE food safe resin?

LLDPE food grade resin pellets are ideal for manufacturers looking to create sustainable, high-quality polymer compounding products that meet FDA standards. These plastic recycling pellets are used in linear low density polyethylene film applications such as food packaging bags, clear produce film, shrink wrap for palletized food goods and grocery store flexible packaging.

This PCR plastic offers an eco-friendly food packaging to virgin polyethylene pellets while maintaining strict regulatory (and performance) standards.

How is LLDPE food safe resin made?

The process begins with collecting materials exclusively from carefully vetted food packaging suppliers, such as grocery and food retail locations. These materials are stored on pallets in segregated food-grade silos to prevent contamination.

Once grade is qualified, the film undergoes washing, drying and extrusion using machinery reserved for food safe resin. Before extrusion, all equipment undergoes deep sanitation and line changeovers to prevent cross-contamination with non-food materials. Following extrusion, the polyethylene resin undergoes devolatilization for further purification.

From only using food packaging suppliers to enforcing meticulous quality standards at every stage of production, we create eco-friendly food packaging materials that exceed rigorous FDA standards.

What is devolatilization and why is it important?

Devolatilization is a high-temperature purification process that removes volatile compounds, residual odors and impurities from recycled plastic pellets. For food safe resin, it’s essential — ensuring the final product doesn’t retain any off-odors or substances that could affect the flavor, safety or integrity of packaged goods.

During this process, the material passes through a post-crystallization unit (PCU) (also known as a devolatilizer) which heats the resin and draws out unwanted gases through an exhaust system.

Devolatilization ensures the end product is a resin that food packaging suppliers can always be 100% certain protects the planet and consumers alike.

How are materials for LLDPE food safe resin sourced?

Natura PCR works exclusively with vetted retail partners (like H-E-B and other select food distributors) through structured recycling programs managed by our waste management partner. Only film collected from locations that handle food products is accepted for use in our LLDPE food safe resins.

What is the contamination threshold for LLDPE food safe resin?

Our LLDPE food safe resin must meet a contamination threshold of 3% or less. If a bale exceeds this limit, it’s automatically downgraded to a multi-purpose grade. This high standard ensures the final resin polyethylene is safe for food contact and food and beverage packaging.

If any bale fails to meet food-grade criteria, it is immediately downgraded and used to create general-use multi-purpose LLDPE film.

How are food-grade LLDPE pellets shipped and stored?

Once processed, food-grade polyethylene pellets are packed in FDA compliant plastic packaging materials such as gaylords, supersacks or smaller sample quantities. The pellets are stored in designated food-safe silos and staging areas to prevent contamination.

What are the specs for LLDPE food safe resin?

Natura PCR’s food safe resin is designed for FDA-compliant packaging applications, ensuring safety, purity and consistent performance. Key specifications include:

- Melt Flow Index (190°C / 2.16kg): 0.6–1.5 g/10 min

- Density: 0.917–0.920 g/cm³

- Contamination Level: ≤3% (visual)

- Moisture Content: <0.30%

- Color: Clear / Natural (food-safe)

- Form: Pelletized

- Tensile Strength: 14–22 MPa (minimum)

- Elongation at Break: 300–600% (typical)

What is multi-purpose LLDPE film?

Multi-purpose LLDPE film is a tough, durable polyethylene resin engineered for applications that require flexibility with added strength. Unlike LDPE, which has a highly branched structure, linear low density polyethylene (LLDPE) has short, uniform branches. This molecular structure boosts tensile strength and puncture resistance.

What are the best uses for multi-purpose LLDPE film?

Multi-purpose LLDPE film is a go-to material for high-performance, strength-driven applications across the industrial packaging space. It is widely used in polymer compounding as a sustainable alternative to virgin plastic resin pellets. Its flexibility and resilience make it ideal for shrink wrap on pallets, stretch film for secure transport and flexible packaging for various products. This polyethylene resin is also commonly used to manufacture heavy-duty liners where picture strength is crucial.

How are materials for multi-purpose LLDPE film sourced?

The raw materials used to create multi-purpose LLDPE film come from a reliable and traceable network of major retailers and commercial distribution centers, including brands like Amazon, Walmart and Ashley Furniture.

How is multi-purpose LLDPE film made?

Once collected, the baled film is staged in our facility and processed through a rigorous recycling and extrusion process. The material is washed, dried, melted and pelletized using the same machinery as other non-food grade resins.

What is the contamination threshold for multi-purpose LLDPE film?

Our contamination threshold for LLDPE multi-purpose resin is capped at 10%, though in practice, our contamination rate is often much lower — typically around 5%.

Through total partnership with our suppliers, we can identigy, report and mitigate issues through corrective action reports and ensure total control over input quality.

What are the specs for multi-purpose LLDPE film?

Natura PCR’s multi-purpose LLDPE film is engineered for demanding applications that require both strength and flexibility. Key specifications include:

- Melt Flow Index (190°C / 2.16kg): 0.5–2.0 g/10 min

- Density: 0.917–0.925 g/cm³

- Contamination Level: ≤10% (visual)

- Moisture Content: <0.50%

- Color: Mixed (available in natural and custom colors)

- Form: Pelletized

- Tensile Strength: 12–20 MPa (minimum)

- Elongation at Break: 500–800% (typical)

The Clean Path to Compliance: How We Produce Food Safe Resin

From sourcing and segregation to devolatilization and storage, discover the rigorous processes that ensure every batch of recycled plastic resin pellets meets the highest standards for purity, safety and regulatory standards.

Elevated Everyday Performance

What is LDPE plastic?

LDPE, or low density polyethylene resin, is a lightweight, flexible and durable polyethylene resin used in a wide range of consumer and industrial applications. At Natura PCR, our LDPE multi-purpose grade is a PCR recycled material — meaning it’s made from 100% post-consumer recycled materials sourced from meticulously vetted commercial partners. LDPE resin polyethylene offers a more sustainable, circular solution to virgin plastic resin pellets without sacrificing practical performance.

What are the best uses for low density polyethylene resin?

Low density polyethylene resin is best suited for applications that prioritize flexibility over tensile strength. This includes everyday and disposable packaging items like plastic bags, LDPE polythene wraps, bubble wrap, recycled plastic pellets for tubing and ring carriers for six-packs.

LDPE is also used in polymer compounding for less demanding product applications that don’t require the rigidity or high impact resistance found in materials like high density polyethylene pellets. LDPE multi-purpose grade is a preferred material for converters and polypropylene manufacturers in the USA looking for efficient, eco-conscious plastic solutions.

How are LDPE pellets made?

Our LDPE pellets are manufactured through a closed-loop PCR recycling process. First, clean and consistent post-commercial film is collected from vetted retailers. This feedstock is then baled, sorted and subjected to a rigorous decontamination and extrusion process. Using state-of-the-art optical cameras, washing systems and filtration technologies, we remove up to 90% of impurities before converting the material into high-quality plastic resin pellets. These LDPE pellets are then tested and classified based on application requirements and end-use functionality.

How is low density polyethylene sourced?

Unlike typical plastic recycling pellets that rely on residential recycling streams, Natura PCR sources LDPE polyethylene film exclusively from commercial retailers with a consistent stream of post-use film. This includes store locations like Rooms to Go, Ashley Furniture, Amazon warehouses and Walmart stores, where clear film wrap from shipping and stocking processes is collected, baled and transported to our facility through our partnership with waste management companies. This feedstock typically consists of shrink wrap, clear plastic film and other uniform materials used in shipping and stocking.

How does controlled sourcing improve LDPE resin quality?

Because this material comes from known, repeatable sources, we can monitor and manage the contamination profile with precision. Unlike other PCR recycled materials, which often contain unpredictable items like paper labels, food residue, diapers or even sharp objects — our LDPE polyethylene film feedstock is cleaner from the start. The result? Fewer contaminants, better performance and less variability in the finished LDPE pellets.

What is the LDPE melting point?

The LDPE melting point typically ranges between 105°C and 115°C, which makes it ideal for low-temperature processing environments and everyday packaging production. This relatively low melting range enhances ease of molding and extrusion, making LDPE a reliable material for applications where thermal efficiency and pliability are essential.

Are Natura PCR’s LDPE pellets food-safe?

Our LDPE multi-purpose grade is not currently classified as a food-safe resin. However, our LLDPE food-grade resin is made exclusively from FDA-compliant post-commercial feedstock collected from food distribution centers. These materials go through a stricter grading and segregation process and are processed on designated food-grade equipment.

What is the contamination percentage for LDPE resin?

With our advanced quality control processes, we eliminate up to 90% of these contaminants to deliver consistent and reliable polyethylene pellets.

What contaminants are found in LDPE resin?

The most common contaminants in LDPE plastic resin pellets include paper labels (cellulose), small bits of foam or cardboard from packaging, and occasional wood fragments from furniture deliveries. Unlike residential streams, which may contain food waste or hazardous materials, our commercial feedstock is far cleaner.

Does Natura PCR offer custom LDPE recycled polymer solutions?

Yes. Our team’s custom polymer synthesis service and polymer compounding help our clients meet any unique mechanical or processing specifications. Whether you're looking to match a specific melt flow rate, adjust color or optimize for strength, we offer collaborative R&D support tailored to your application needs.

What are the specs for LDPE resin?

Natura PCR’s LDPE recycled plastic pellets are designed for versatility and everyday performance. Key specifications include:

- Melt Flow Index (190°C / 2.16kg): 0.20–0.60 g/10 min

- Density: 0.920–0.925 g/cm³

- Contamination Level: ≤10% (visual)

- Moisture Content: <0.50%

- Color: Mixed

- Form: Pelletized

These LDPE pellets offer consistent performance for converters looking for reliable polyethylene resin in flexible packaging, film extrusion, and molded goods.

Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo

Dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi aliquip

Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo

Name Surname

Position/Title

Company Name

Peter Goldberg,

Field Manager

Schlumberger

Not Your Average Plastic: How LDPE 150’s Versatility Supports a Circular Economy

Learn how Natura PCR’s multi-purpose LDPE resin powers circularity by giving post-commercial film new life in high-demand applications like tubing, bubble wrap and ring carriers.